Why Customer Love To

Choose Us

We were able to survive this long because of our reputation of good quality job, timely delivery of our services and above all reasonable cost. This would not have been possible without the support of our technically sound people from various sector of fabrication

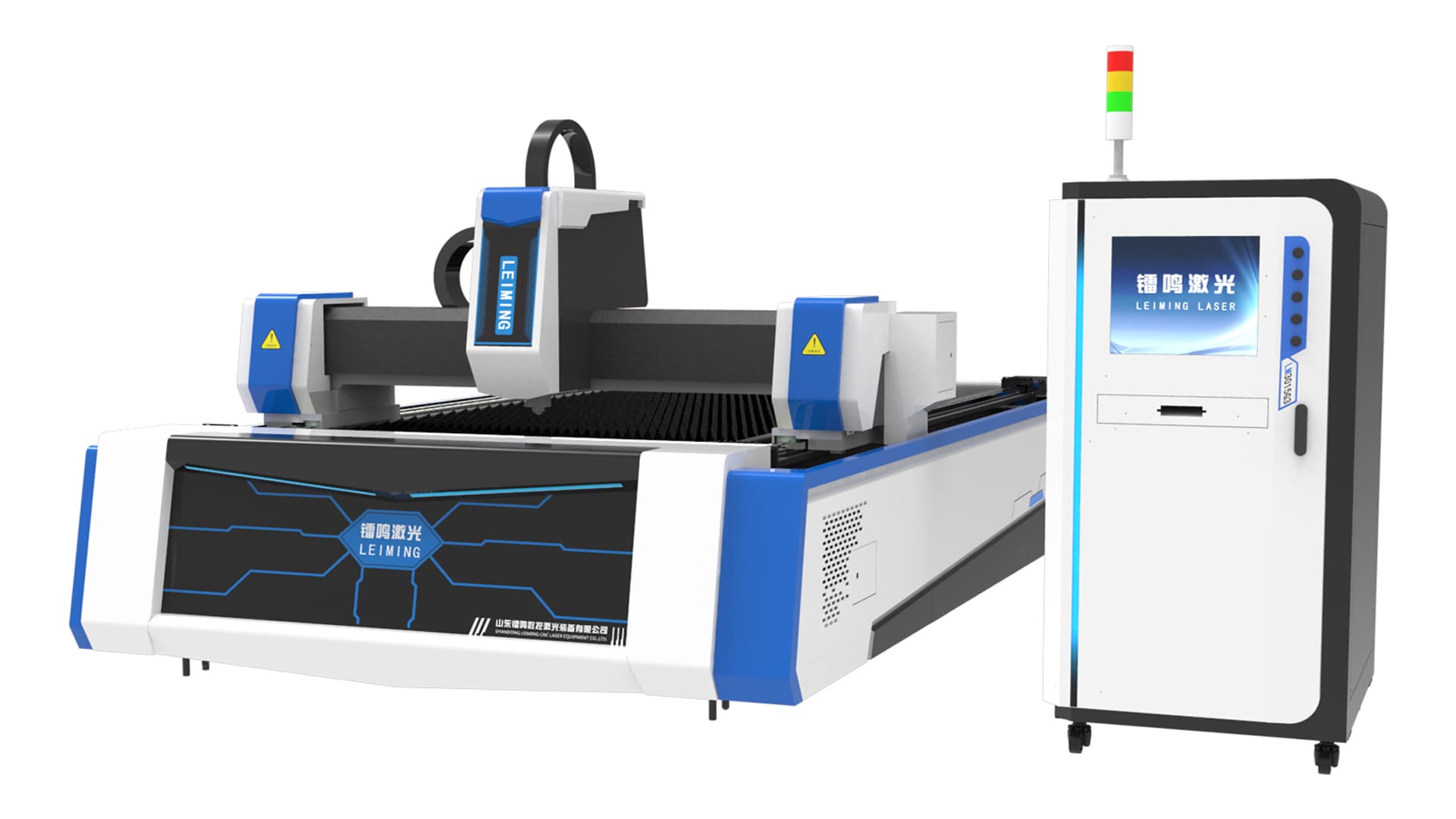

Laser Cutting Machine

Laser cutting machines are controlled by computer numerical control (CNC) systems. The CNC system interprets the design files and controls the movement of the cutting head, as well as other parameters such as cutting speed, power, and focus.

Read MoreWaterjet Cutting Machine

Waterjet cutting machines utilize a high-pressure water pump to generate a focused stream of water. The water pressure typically ranges from 30,000 to 90,000 pounds per square inch (psi) or even higher. The high-pressure water is then mixed with abrasive particles to enhance cutting capabilities.

Read MoreC.N.C. Turn Center

Automation and Precision: CNC Turn Centers offer high levels of automation, allowing for efficient and accurate machining operations. The CNC system controls the movements of the cutting tool, ensuring precise cuts and consistent results.

Read MoreLathe Machines 1mt to 6mt

These are compact lathe machines suitable for small-scale and hobbyist applications. They typically have a swing over the bed of around 200mm to 400mm and a distance between centers of around 300mm to 600mm.

Read MoreMechanical Press

A mechanical press is a machine used in various industries to shape, cut, or form materials through the application of mechanical force. It is a type of machine press that utilizes mechanical energy to carry out its operations.

Read MoreRadial Drills

Radial drills are capable of drilling holes at various angles and positions due to the radial movement of the arm. The movable arm and adjustable column height make radial drills suitable for drilling holes in larger workpieces.

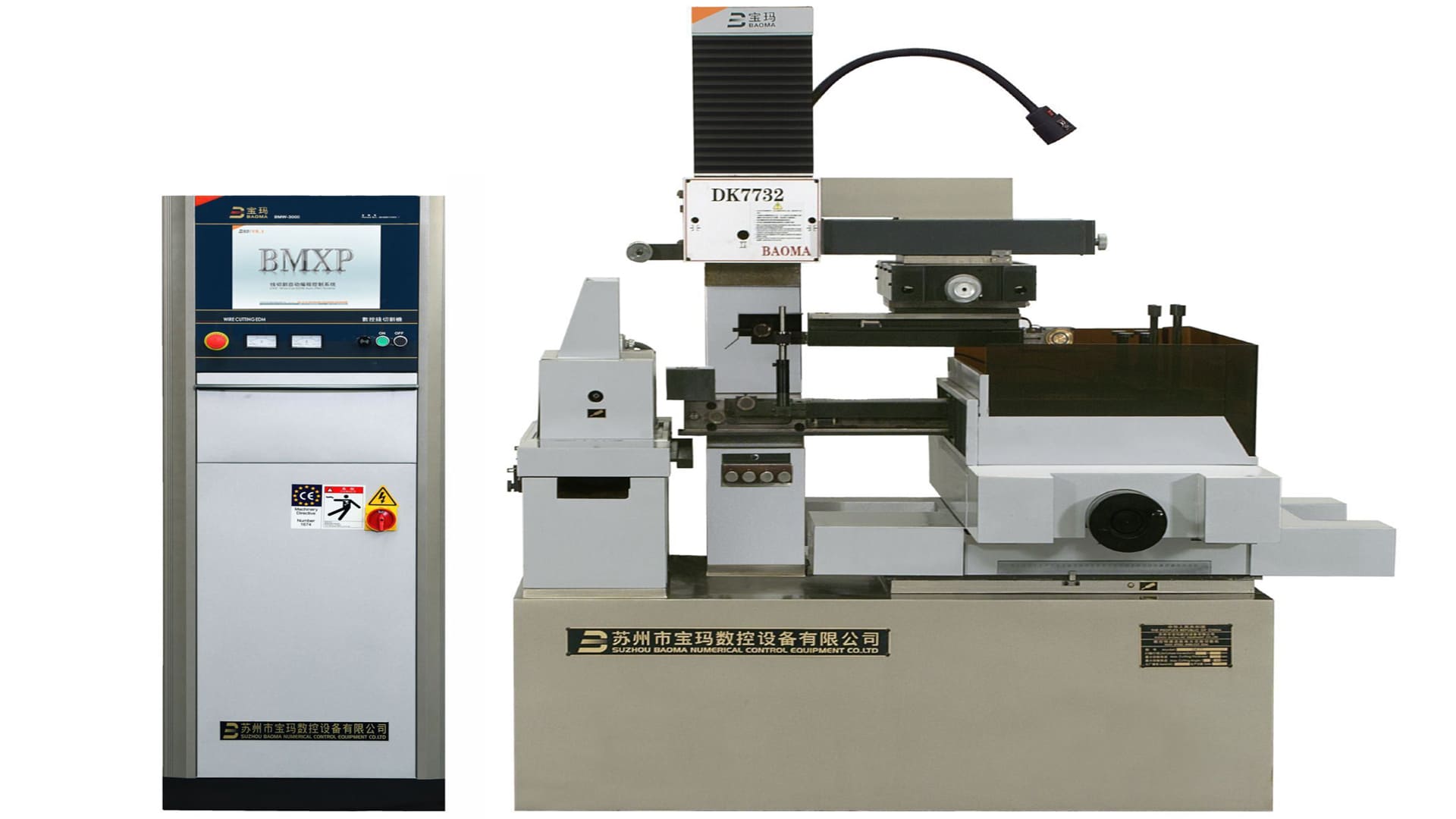

Read MoreWire Cutting

Wire cutting is a manufacturing process used to cut various materials, especially metals, into specific shapes and sizes using a thin, electrically charged wire. The process is also known as wire EDM (Electrical Discharge Machining) or WEDM (Wire Electrical Discharge Machining).

Read MoreEDM Spark

EDM spark refers to the spark or electrical discharge that occurs during Electrical Discharge Machining (EDM), a non-traditional machining process also known as spark erosion, spark machining, or die sinking. EDM is a precision machining method used to create intricate shapes and contours in electrically conductive materials.

Read MoreEDM Wire Cut

EDM wire cutting, also known as Wire Electrical Discharge Machining (WEDM), is a specific variant of Electrical Discharge Machining (EDM). It uses a thin, electrically conductive wire as an electrode to cut complex shapes in electrically conductive materials with high precision.

Read MoreGear Hobbing

Gear hobbing is a specialized machining process used to manufacture gears. It is a form of gear cutting that utilizes a gear hobbing machine to produce gears with specific tooth profiles and sizes. Gear hobbing is widely used in industries such as automotive, aerospace, machinery, and more.

Read MoreOur Specializations

Jannat workshop was founded in the year 1995. We are located in the Dallah Industrial Area in the Eastern Province of the Kingdom of Saudi Arabia.